*Actual Photos

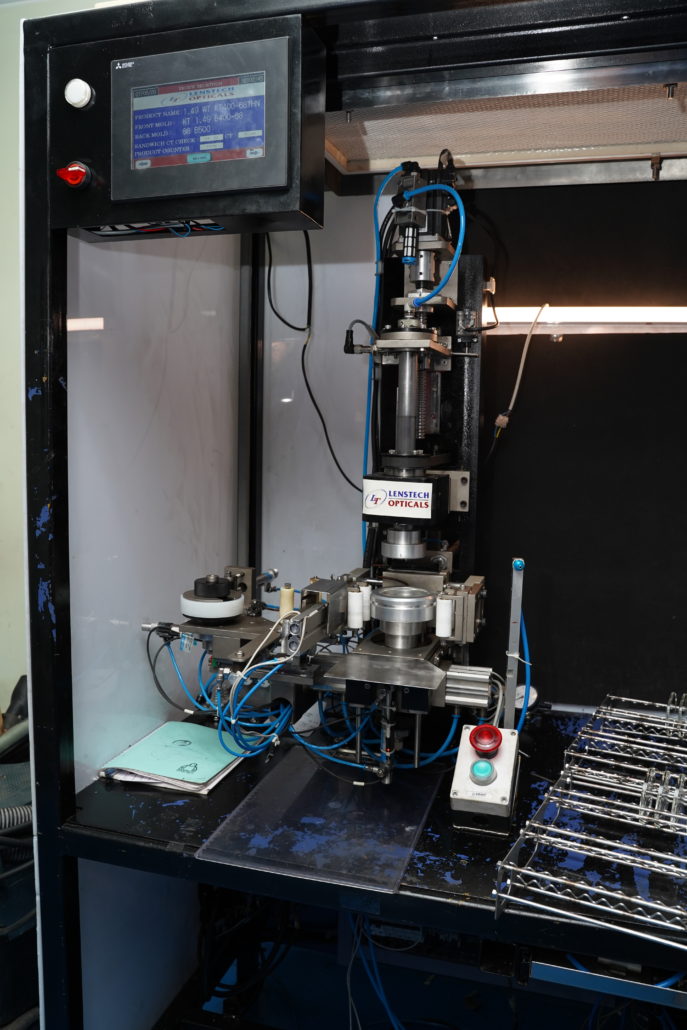

Taping machine

Monomer mixing

Poly Oven

Poly Oven Seq

Filling

Demoulding

QC

Mould & Lens wash

Trays & Trollies

Dia Edging

RESIN LENS CASTING TECHNOLOGY

START YOUR OWN FACTORY FOR MASS PRODUCTION OF LENSES BY CASTING LENSES FROM LIQUID MONOMER AND CATALYST. Capacity from 5000 lenses onwards…

Lenstech Opticals will provide the complete set of machines required for this. Starting with designing the layout of the factory based on available space, planning machine requirement, installation of machines and then detailed production training for a month.

Process in brief : The Glass moulds are selected as per the power to be made and are taped together in the Taping machine, this determines the thickness of the lens. The liquid monomer mixed with a catalyst is then filled into the mould assembly. Once filled with monomer mixture, the mould assembly is put in an Hot air oven for the Polymerisation. The oven is programmed with a temperature / Time cycle which can extend upto 24 hours depending on the material. After this Polymerisation cycle is finished, the lens is removed from the moulds. The lenses are sent for edging to get smooth edges and the moulds are washed and re-used. Finished Stock lenses and Semi-Finished lenses can be made using same equipment.

Big capacity Hard Coating and Anti-Reflection Coating machines are also available.

These lenses are called as Resin, CR or Plastic lenses.

Glass mould making factory can also be installed for making new moulds or repairing old ones.

We have long experience in lens casting and also own Lens casting factory.

All sources of raw material and consumables will be provided.

No Blog Posts found

Available Pages

- 301 Blocker

- About Us

- ALLOY DE BLOCKER

- Anti-Reflection Coating Machines

- AUTOMATIC PROGRESSIVE MARKING (PRINTING)

- AXIS MARKER

- Best Lens Calculator Software

- Blockers

- check

- CNC LENS GENERATOR (VECTOR 7)

- COBALT COMPACT GENERATING SERIES

- COBALT FREE FORM POLISHER

- COBALT-DS INDUSTRIAL GENERATOR

- contac

- Contact Us

- CTL-65 CNC Lens Generators

- DIP HARD COATING MACHINES

- Eclipse

- Free Form (Digital) System

- Fully Automatic Hard Coating Machine

- Gallery

- Gauges

- GEOMETRIC CENTER MARKER

- Leading Machine Manufacturer For Making Spectacle Lenses

- Lens Calculation Programme

- LENS DIA CRIBBER

- Lens Marking Machines

- Lens Preparations Units

- Lens Surfacing Machines

- Mist Marking (FOG) : MM-2

- Mist Marking (FOG): MM-1

- N800 Fining Tank S.S

- N800 Polish Tank S.S

- N800 Toric Lens Surfacer

- N900 Toric Lens Generator

- New Products | RESIN LENS CASTING TECHNOLOGY

- Optical Lens Surfacing Machine

- ORlON-40T ANTI-REFLECTIVE COATING SYSTEM

- PNEUMATIC TAPE APPLICATOR

- Products

- SAG GAUGES

- SEMI AUTOMATIC 8T

- SEMI AUTOMATIC PROGRESSIVE MARKING

- slider

- slider

- Thankyou

- THICKNESS GAUGES

- TOOL RACK

- Wax Blockers

Archives by Subject:

- No categories