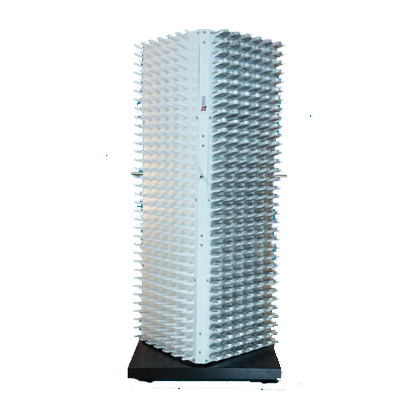

OPTICAL LENS SURFACING MACHINE

In the good old days, the concept of optical lens surfacing machine was essentially associated with traditional lens alone. However, diversification of markets has led to a range of units introducing one of its kind optical surfacing equipment that can take care of people’s digital needs as well. Ophthalmologists generally look out for high quality lens, which put forth wholesome level of finishing. This can be ensured by making use of superior quality inputs in the processes that go behind rolling out any kind of lens generator equipment at large. Hence, it will not be wrong to state that both survival and success of manufacturers of these equipments largely depends on the amount of predominance they lay down on the excellence parameter.

The above facts hold true in case of an optical lens generator as well. Moreover, if you are looking forward to invest in one such equipment, then it is critical that you pay heed to some factors like automation, performance and outcome and also the add ons.

Automation is the Key: Each optical lens generator tends to differ from its counterparts on the basis of a couple of distinguished elements. One such area of distinction is that of automation. In the market, you can easily find a generator that is fully automated to something, which involves heavy manual assistance. If you wish to add a tinge of sophistication and simplicity to the surfacing process, then don’t think twice before settling for the former.

Add On Activities: When we talk about optical lens surfacing machine, it is obvious to understand that before you derive the final product, the lenses need to go through a series of steps. Now, if you purchase individual machines to proceed with each of these functions, you are sure to face both space as well as financial constraints. But, this obstacle can be totally be done away with by investing in one such lens generator equipment that is capable of performing several functions all by itself. This would indeed work out to be a cost effective solution.

Outcome & Performance: Yet another factor that plays a pivotal role in the process of selecting optical surfacing equipment is the speed and performance the said machine is capable of generating. When time plays a vital role, it is obvious that you would like to get your hands on one such machine that guarantees not just reliability, but also the ability to generate output that surpasses their expectations and more. If this is done, lethargy and heavy time consumption can totally be done away with.

You will indeed be able to make an accurate decision with regards to the aforementioned aspects, only when you take out the time to study the various alternatives that are available up for sale. One of the best ways of making a near perfect decision is to carry out a comparative study between the different surfacing equipments. Pricing should not be the only factor on the basis of which you tend to take the final call. This is because even if you end up purchasing equipment, which is comparatively low priced, you might end up spending much more on its maintenance at a later stage.

Quite a lot has been said and heard about traditional and digital surfacing of lenses. But, one alarming difference that gives digital surfacing an upper hand, in comparison traditional surfacing is its capability to explore the angle of customization. If optical lens surfacing machine needs to be carried out in a way that it best suits a particular requirements, then it is obvious to pick out digital surfacing over the traditional one. Click here to check Fog Marking Machines.

Our Similar Products

Lenstech Opticals, Coburn Technologies, Norville Autoflow & Vtc.

Products

Contact Us

Mobile: +91-9820141639

Phone: +91-22-27411303/04

naveen@lenstechopticals.com

sales@lenstechopticals.com

Address

Plot 17/3, M.I.D.C, Taloja,

Opp. Dena Bank, Navi Mumbai,

Maharashtra, India.

Pincode: 410208